Components

Airex has literally 70 years of experience producing an array of high-quality electromagnetic components found in the most critical applications ranging from the highest-performing military guidance systems to the most demanding semiconductor manufacturing operations.

Our parts have been utilized in:

- Imaging on unmanned deep space missions

- Electromagnetic sensors for invasive medical catheters

- Controlling position and speed in diamond turning and grinding applications

- Ultra-smooth, vibration-free motion for extremely high-resolution lithography

- Propulsion for unmanned deep sea exploration vehicles

- Guidance systems for the most advanced aircraft and missile systems

- Inter-satellite communications systems

- Establishing standards for the National Institute of Standards & Technology (NIST)

- New standards for the Korea Research Institute of Standards and Science (KRISS)

- And many more…

Airex’s expertise resides in the practical customization of ultra-high-end products. We’ll take on specialized manufacturing as a fully integrated, value-adding feature that utilizes our advanced systems. Our focus is providing your exact component at a competitive cost point, tested and ready for you to integrate. Within our custom manufacturing group we offer design, development and process improvement services to achieve the right fit for your application. This same process can apply to our line of high-quality, high-performance commercial brushless linear motors, which are also fully customizable.

Let us be your next phone call when you require design, prototyping or manufacturing of advanced electromagnetic devices such as:

- Resolvers

- Spin motors

- Torque motors

- Synchros

- Rotary transformers

- Signal transformers

- Voice Coils

- Active Magnetic levitation actuators

- Rotary brushless motors

- Electromagnetic Actuators

Airex linear motor performance advantage

If extreme efficiency, velocity control or fast settling time is your goal, our patented coil technology is probably right for you. We have a history of delivering the highest-performing linear motors and electromechanical components, and we will work to meet your definition of “best-in-class performance”.

At Airex, performance does not just equal speed. Accurate, fast positioning requires rapid settling, enabled by our industry-leading electrical time constant. Smooth, constant velocity requires uniform magnetic fields and precise electrical and magnetic phase matching. Precise, fluid motion requires excellent heat management and predictability.

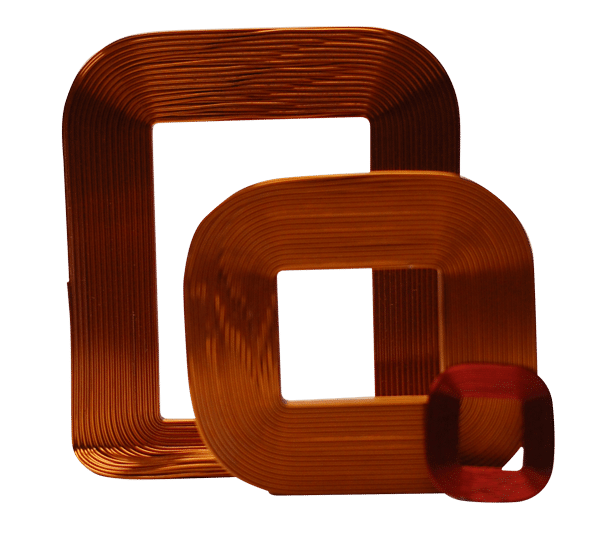

The key to our high performance is the accuracy and repeatability with which we wind coils and place magnets. All Airex linear motor coils are wound using our patented CNC-based winding machines. These robotic machines accurately and rapidly place every conductor while minimizing end turns, allowing us to balance magnetic and electrical properties. Not only do we design our own machines, but the latest generation of Airex winding machines incorporate our linear motors for unmatched speed and accuracy. Additionally, we use patented machines that form precisely shaped coil modules from the wound coils. The modules enable ease of manufacturing while maintaining exceptional heat transfer in the finished product.

Our linear motors in the C-, I- and P-Series are fully customizable. If you see a motor that almost fits your needs, we can modify it to meet your exact specifications and enable you to design precise integration for your system. We engineer and design the highest-performing product that will suit your requirements whatever they may be.

Motors & more

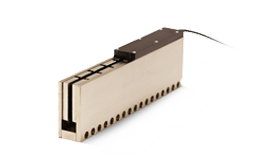

Ironless Linear Motors

If you’re looking for the most accurate linear motor available, this is it. If you need high acceleration and speed, high bandwidth, reduced settling time and low-velocity ripple – no matter the speed – Airex has the solution. These linear motors offer a variety of distinctions, such as:

- Lower moving mass

- Lower inductance

- Lower losses

- Well-contained magnetic fields

- Higher stiffness

- Higher peak force capacity

Plus, we can customize any motor to your exact specifications and requirements.

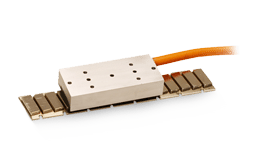

Iron Core Linear Motors

Airex proprietary winding designs make powerful, compact motors that deliver exacting performance time after time without overheating. Inside are high-performance, rare earth magnets. Each customizable motor model features:

- An ironless coil for reduced-cogging.

- Unique toothless technology.

- A patented low-inductance coil design enabling fast response and low settling time.

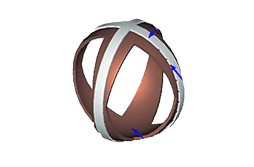

Rotary Motors

Power arrives in small packages. Your high-end motion system will benefit from the dynamic performance and ultra-low-cogging of the Airex toothless rotary motors. Kit-type rotary motors can also be customized to fit your demanding environments, including vacuum and cleanroom preparation.

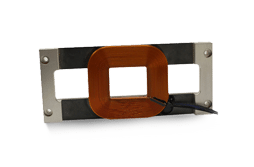

Voice Coils

Your testing and analysis stations require a long-lasting, reliable solution. Consider implementing our voice coil actuators and custom voice coil assemblies for high-demand projects that require wide bandwidth and top accuracy.

Magnetic Bearings

Our development of both Lorenz and Maxwell magnetic bearing actuators is unmatched in both the military and commercial applications. Components offer low-speed positioning, super low-velocity ripple and infinite stiffness in both rotary and linear motor configurations.

The breadth of industries provides for different applications, yet all have the common need for our designs that yield highly-desired performance attributes such as:

- Stable pointing

- Smooth moving

- Accurate positioning

- Low-heating

- Long life

- Vacuum compatibility

Airex’s efforts support and enable space exploration by supplying key magnetics that extend from early missions around planet earth to missions to Mars and Saturn.

We have helped to advance medical technology by providing wound magnetics for applications ranging from patient isolation to high-bandwidth, invasive ultrasonic imaging.

The semiconductor industry applies our actuators in areas of super-high-precision, such as high-speed beam profiling, the precise positioning of reticules, measuring applications and in masks and wafers for exposure in wafer scanning.

Airex’s ultra-precise linear motors power the direct cutting and grinding of glass lenses to a shape better than 1/20th of a wavelength. Our commercial line of motors assists in optical measuring applications due to their low heat rise and wide bandwidth high force with predictable thermal performance.

Our magnetics benefit the highest-level guidance systems, including components such as:

- Resolvers

- Magnetic suspensions

- Torquers

- Spin motors

- Rotary transformers

We cover a variety of industries, including aerospace, military, semiconductor, life science, solar and photonics. If you require a motor or other wound magnetic device customized for your specific needs, we have the solution. Our linear and rotary motors, voice coil actuators, and magnetic bearings easily adapt to fit nearly every need. However, if our existing technology doesn’t exactly match your requirement, we’ll design and build what you need from scratch.

Ready to connect on how Airex can address your specific needs?