About Airex

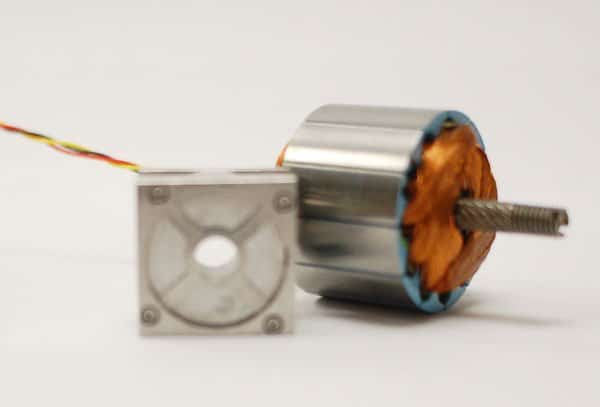

Best-in-class linear motors

Airex manufactures precision-wound components for industries that require top-performance motoring. Our patented winding technology and robotic methodology knowledge is unmatched, assuring you best-in-class quality linear motors, rotary motors and voice coils.

Company Overview

Airex brings the virtues of small company dedication with more than 60 years of expertise to the marketplace. We apply our technology to both domestic and international markets. We believe that the quality of service to our customers and the products we produce provide end-users with the best opportunity to succeed in a very competitive environment.

We continue to develop our technology base as a fundamental component of our mission. Product innovation will introduce new opportunities for our customers in the markets they serve. While our low cogging rotary motor was once termed “the quietest motor ever tested in this country”, our linear designs are now credited with the highest thermal efficiency. This focus on performance has been acknowledged with a variety of new contracts awarded in both product development and manufacturing areas. We have also received international recognition, and numerous patent awards as a result of the company’s innovative thinking and groundbreaking implementation of technology.

We will continue to implement our designs in high performance markets. We anticipate new technology in magnetic bearings applicable to the semiconductor market, the medical industry, the US defense program in space and the European space program. Automated manufacturing systems and numerous other markets are candidates for this technology as it matures. The common thread through these markets will be the requirement for cutting edge performance and the highest levels of quality.

Certification

AS9100 certification is an essential component of our quality system, as it allows Airex to provide the highest quality components to the aerospace industry. International Traffic in Arms Regulations (ITAR) to protect technology and technical information are also integrated to Airex systems.

As an AS9100 certified organization, our Quality Management System sustains our standards from initial design to final manufacturing tasks. With constant focus on customer needs, we continue a tradition for the highest quality of every product we manufacture and service we offer. Airex provides the highest quality experience at every level of our organization.

Airex Quality Policy

Airex delivers structured, rigorous, world-class quality that exceeds customer and market expectations. We pledge to apply our resources to continuous improvement to maintain and exceed our best-in-class brand and expand our market knowledge resulting in an expanded market share and customer base.

Project timeline highlights

1961

Airex begins coil winding for National Defense Missile Systems

1968

First automated winding machine development for Bendix gyroscopes

1976

Guidance system development with Draper Laboratories

1980

Zig-Zag winding patent for reduced end turn torque motors – USAF SFIR/Navy 10 PIGA

1988

Quality system revitalized for space flight for Martin Marietta/NASA Mars Explorer Mission

1998

Automated work cells introduced

2003

Commercial success with patented linear motor

2004

Custom voice coils engineering for MKS gas chromatography

2005

Gyro component engineering for US Army Blackhawk/Chinook helicopter retrofit

2006

Airex introduces patented magnetic bearings to the marketplace

2009

Linear actuator product launched with Schneeberger Partnership

2010

Spherical voice coil engineering for imaging – General Dynamics Gordon Stare program

2011

C12/P16 linear motor introductions for Apple iPad manufacturing

2012

Innovative voice coils designed for Speedline material deposition

2013

Begin manufacturing for Honeywell Strategic Missile Guidance Systems

2014

Rotary motors engineered for Lockheed Integrated Defense Technologies

2015

C10/C16 linear motor introductions for international markets

2016

Ultra-low-cogging rotary motor engineering for Quartus Space-based Optical Positioning Gimbal

2018

PIGA Strategic Missile Defense Program collaboration and manufacturing with Draper

Certifications and quality management

Airex AS9100 certification communicates our commitment to quality products and services. AS9100 requirements and the Airex Quality System are continually updated and implemented, and procedures are documented consistently. Our current certification is valid through October 8, 2020.

The AS9100 Quality Management System applies to every aspect of design, manufacture, test, inspection, delivery and administrative duties performed on a daily basis at Airex. All Airex employees are responsible for quality in every function of the organization and individual job descriptions. Each team member receives training in specific skills appropriate to the required tasks, which assists them in applying our high standard of quality.

The Airex Quality System utilizes both external and internal analysis. Annual reviews include benchmarking of product/quality performance in the marketplace as well as internal audits and review of the quality system at the organizational level.

The Airex Quality Management System consists of defined procedures which describe the organization, authority, responsibility and verification activities of Airex to ensure product conformance to specified requirements.

We believe that our approach to quality, both in service to our customers and in the products we manufacture, provides end-users with the best opportunity to succeed in the global marketplace.

Lean manufacturing as a value add

Airex fundamental belief in lean manufacturing provides a path to continuous improvement in the production of your customized or commercial components. Quality assurance and complete solutions to your company standards are our commitments to you. We stand behind the best-in-class designations for the uniformity and repeatability of our linear motors and custom components.

Off-the-shelf motors cannot compete with the performance of our linear motors and components, and chances are, if you’re our customer, off-the-shelf motors do not exist for your specific needs. Airex manufactures custom, precision-wound components for the highest degree of accuracy, which is why they’ve been utilized in aerospace projects and high-performance commercial applications for decades. Your specific requirements for value engineered components are met and often exceeded via our patented technology and robotic methodology.

Market demand for the highest levels of performance demands our unique coil winding process, material science technologies and best-in-class thermal performance.

We maintain a workplace culture where innovation is expected, creativity is encouraged and commitment is honored. The environment has evolved with company growth and the advancement of every team member. Our Board of Advisors provides the structure and discipline to meet the challenges of the next stage of growth, as we commemorate our third generation of leadership.

Ready to provide answers to your detailed queries.