Engineering & Design

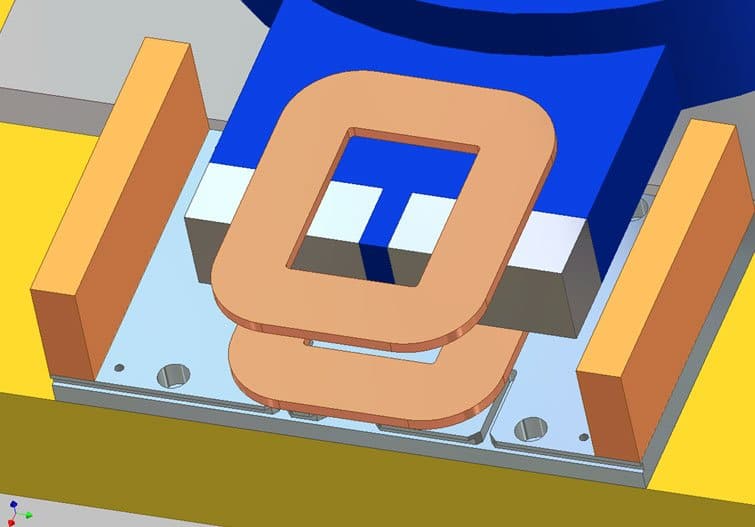

The way the coil is wound is the heart of our motor.

Airex’s patented winding technology helps facilitate accurate drum scanning, printing — and even perform under water as ultra-quiet rotary motors used for UUV thrusters.

Airex may have begun in plastics 70 years ago but, today, copper coil winding is what makes our motors second-to-none in a variety of industries. Our engineering and design team understands the idiosyncrasies of building the most accurate electromechanical motor, which sets Airex apart from the pack of motor production companies (who sometimes confuse speed for accuracy). Our experts are constantly working together to utilize material science and technology advancements to build a better electrical motor than our competition.

In other words, whatever precision you are trying to achieve with your project, we can provide that level of accuracy.

In a Class of Our Own

Inspiring harder questions with better answers is how we approach every conversation with you. It’s how we determine your specific needs and how we can best meet them together. Our engineering team is dedicated to taking the time to ask these questions in order to demonstrate that we can make what you previously thought impossible, possible. We also approach every production to end with a component of the highest degree of repeatability and accuracy, which is why we can confidently say, Airex produces components that no one else can produce.

Automated coil winding

Airex in-house engineering experts wrote and perfected the software for automated machine winding. Hand winding accomplished many tasks in the past, but had its faults in human error. Machine winding simply produces a quality level and a speed that’s not humanly possible.

Value-added service

One of the unique things we do once a motor is assembled is “a burn-in.” We put 100% power into the motor, heating it to its maximum operating temperature, concurrently testing it to ensure its thermal sensors function and it doesn’t have any intermittent connections. This tactic also boils off volatiles so the motor is now more suitable for vacuum or cleanroom operation. This built-in quality is a value-add for your systems.

AS9100 certified

It’s important for Airex to maintain the additional requirements for AS9100 certification beyond the now-standard ISO 9001 requirements, so we can continue providing top services for aerospace organizations. Look to Airex to provide the highest quality products and processes for your next project.

International Traffic in Arms Regulations

ITAR are government rules controlling the export and import of defense-related technology and services. Trust Airex to operate under ITAR regulations and to maintain ITAR control in order to keep technical information only in front of those designated to access it.

Ready to connect on how Airex can address your specific needs?