Semiconductor Strategists

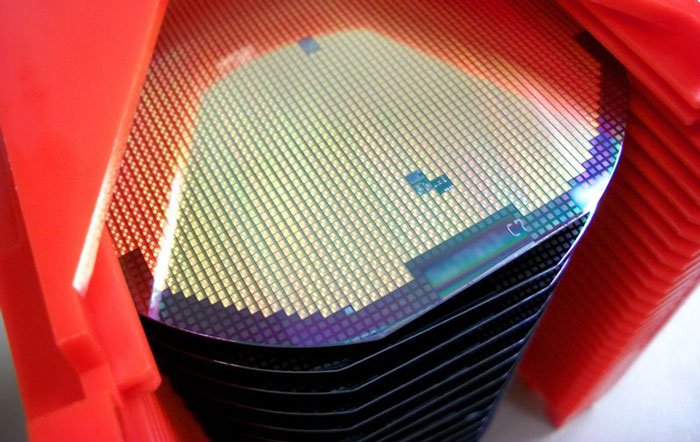

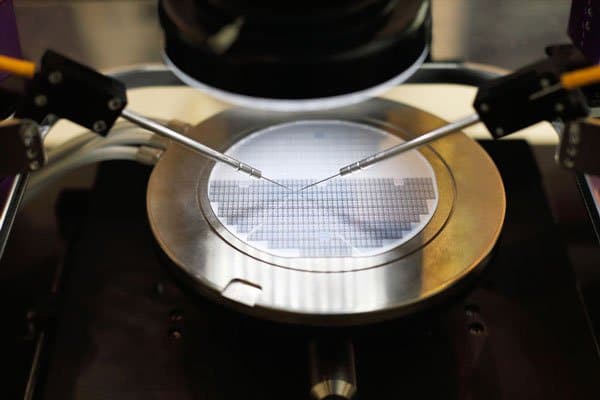

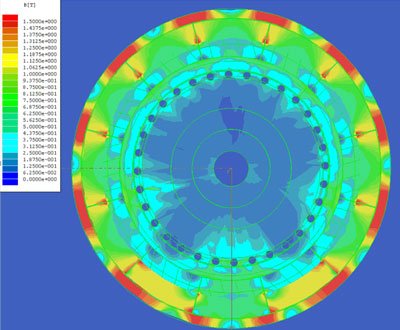

Airex’s patented motor advancements are integral to equipment designed to effectively double the usable surface area on semiconductor wafers. Their linear motors and positioners are finely tuned to nanometer-level accuracy—equivalent to one hundred millionth of an inch—increasing wafer surface utilization to approximately 98%. These motors precisely guide wafer positioning throughout various stages of processing.

The development of Airex’s C-series motors enables semiconductor producers to access the wafers’ farthest corners, enhancing manufacturing precision. The C-series motors are also pivotal in pick-and-place applications involving small component deployment and testing.

These motors play a crucial role in the production of hundreds of advanced technology products, including handheld devices and smart technologies. In semiconductor manufacturing, motor performance—covering positioning, settling, and heating—is as critical as speed when aiming for utmost accuracy over rapid production. Airex’s in-house robotic winding machines ensure the highest degree of conductor positioning accuracy, resulting in top-tier production motors for the semiconductor industry.

Additionally, Airex’s magnetic suspensions support optical guidance and focusing for high-resolution lithography applications.

Career Highlights

- Airex’s patented motor design optimizes output power, ensuring consistent high performance crucial for intensive duty cycle operations in semiconductor chip wafer production.

- Airex’s team developed an ironless linear motor with reduced settling time and minimal velocity ripple, designed to operate at exceptionally low speeds without overheating.

- Airex motors play a critical role in pick-and-place systems within semiconductor PCB assemblies, facilitating placement, inspection, and testing processes.

- Additionally, Airex actuators were engineered specifically to apply precise adhesive for shock loading in personal devices. Key component attributes such as move profiles for acceleration, dither, shake, vibration, and speed were meticulously designed to ensure program success.

Benefit from Airex Expertise

Ready to connect on how Airex can address your specific needs?