Iron Core Linear Motors

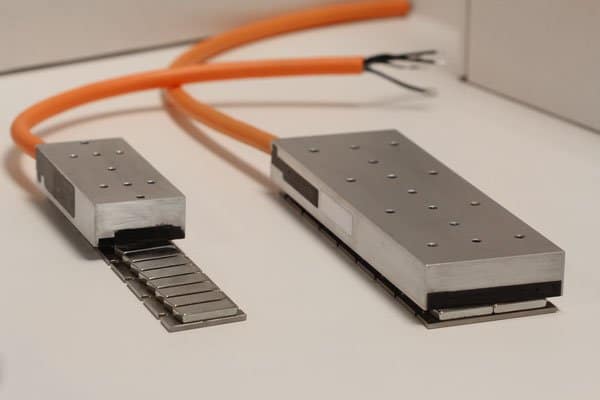

The I38 is our most-compact iron core linear motor, with a profile of 33.6 by 53.4 mm

The I38 is our most-compact iron core linear motor, with a profile of 33.6 by 53.4 mm- Predictable Preload

- Continuous forces up to 213.6 N (48 lb), peak forces up to 996 N (224 lb)

- Reduced-cogging design

- Cost effective modular magnet track.

- High-efficiency thermal path

The I70 iron core linear motor features a low-height (35mm by 82.6mm) solution for industrial linear motion applications

The I70 iron core linear motor features a low-height (35mm by 82.6mm) solution for industrial linear motion applications- High force

- Predictable Preload

- Continuous forces up to 437.6 N (98.4 lb), peak forces up to 804 N (181 lb)

- Reduced-cogging design

- Cost-effective modular magnet track.

- High-efficiency thermal path

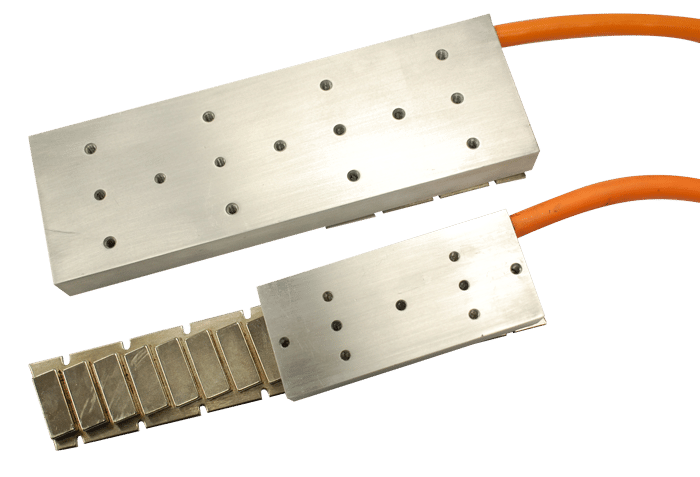

The I100 iron core linear motor features a low-height (113.1mm by 33.5mm) solution for industrial linear motion applications

The I100 iron core linear motor features a low-height (113.1mm by 33.5mm) solution for industrial linear motion applications- High force

- Predictable Preload

- Continuous forces up to 961.1 N (216.1 lb), peak forces up to 1324 N (298 lb)

- Reduced-cogging design

- Cost-effective modular magnet track.

- High-efficiency thermal path

Unmatched performance

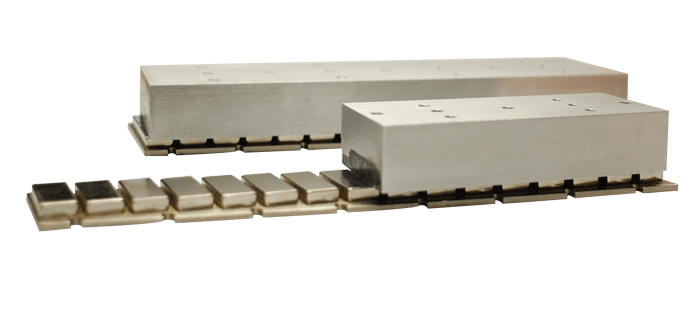

Airex manufacturing method for coils ensures precision placement of the conductors to provide the highest slot fill in the industry. These elements provide an exceptional thermal path for heat to dissipate out of the coil. Our coil design maintains a constant and consistent attractive force, and provides very low levels of cogging and saliency as compared to other systems. The built-in preload allows longer motion platforms to be designed for preload in one direction for rigidity while moving over long spans.

High-temperature rare earth magnets are used in the creation of the Airex magnet plates. These modular plates allow for the construction of very long magnet tracks. The steel components and magnets are nickel plated for a long, corrosion-free life.

These motors are ideal for producing high forces in point-to-point and constant velocity applications. The motors feature fast point-to-point settling times — not typically found in our competitor’s motors.

Ironless linear motor applications

- Alignment and positioning platforms

- Assembly processes

- Machine tools

- Solar panel fabrication

- Laser scribing and inspection systems requiring precise control and repeatable positioning

- Flat panel display inspection and processing

- Solar assembly, inspection and scribing applications

- Large-format printing applications

- High-speed semiconductor inspection machines

- Liquid handling and delivery, microplate robotics

- Precision laser cutting, engraving, substrate dicing

- Cutting and grinding XY platforms

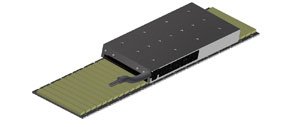

I-Series features

- Constant z-axis attractive force for superior stability

- Low electrical time constant for high accuracy/repeatability and fast settling times

- Motor maximized for efficient thermal performance

- Velocities up to 5M/sec, accelerations greater than 10G

- No maintenance, non-contact brushless design

- Optional Hall effect commutation

- Proprietary winding design for maximum slot fill

- Low-inductance coil for fast response

- Custom options (thermal sensors, water cooling, cabling, vacuum/clean room quality) available

- Simple installation – top mount coil and three standard-length tracks with mounting holes for virtually endless travel

Ready to connect on how Airex can address your specific needs?