Aerospace Ally

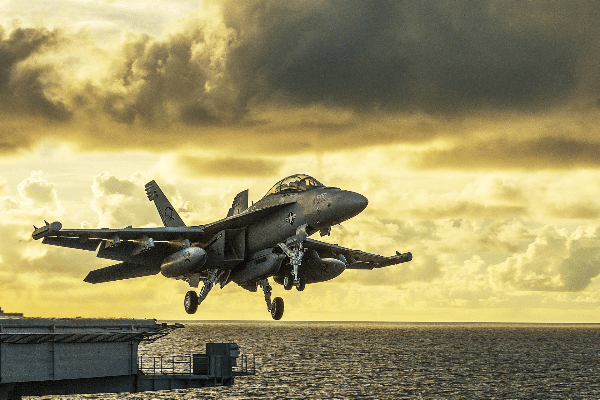

Discover Airex’s distinguished legacy in aerospace innovation spanning decades of pivotal partnerships. Their expertise shines in engineering cutting-edge wound-magnetic assemblies for gyro motors used in advanced air-to-air missile systems and powering exclusive guidance systems for Blackhawk and Chinook Helicopter flight systems.

Collaborating closely with the aerospace industry, Airex conducts meticulous feasibility studies to optimize custom component designs, ensuring seamless integration of durability and energy efficiency from prototype to production.

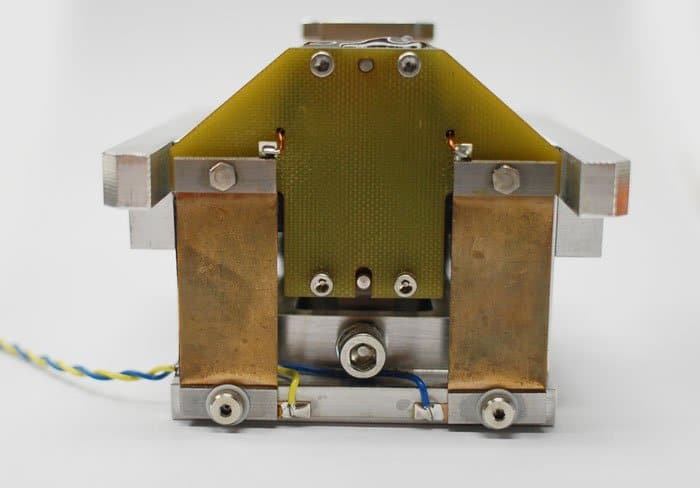

Airex prioritizes efficient heat management in aerospace applications. Their motors operate at lower temperatures, leveraging advanced winding technology with optimized copper density in electromagnetic circuits, delivering reliable performance where energy conservation is critical.

Pioneers in manufacturing, Airex’s robotic winding machines are equipped with state-of-the-art optical sensors and closed-loop servo systems, incorporating proprietary linear motors for unparalleled precision.

Addressing unique aerospace challenges, Airex specializes in low-outgassing solutions, providing essential venting for mounting surfaces to enhance operational reliability.

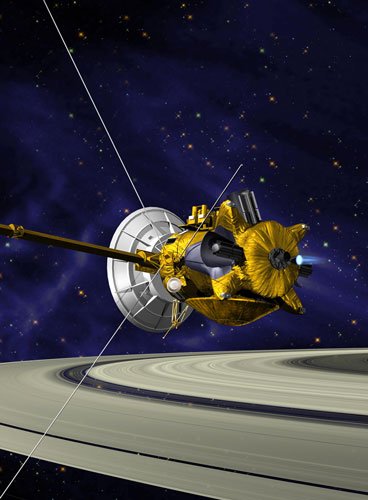

Driven by fundamental physics, Airex’s designs are engineered to excel within stringent voltage limitations, ensuring precise payload movement and reliability during extended missions across vast distances from Earth.

Explore how Airex continues to lead innovation in aerospace technology, setting new standards for performance, reliability, and efficiency.

Career Highlights

- Advanced fighter jets benefit from Airex’s designed and developed torque motors, deployed in tens of thousands of gyro motors.

- Helicopter guidance systems rely on Airex’s long-life components for high reliability and extreme accuracy.

- Airex-designed components in missile systems ensure fast response and extreme precision over many decades of service.

- Airex’s team collaborated with Louisiana State University and the University of Kentucky to design and develop magnetic bearing prototypes for satellite antenna pointing systems, based on MILSTAR requirements.

- The Mission to Planet Earth program utilized Airex’s low-cogging motors for Jet Propulsion Laboratory systems analysis and flight unit evaluation.

- Airex’s space flight-quality transformers were pivotal in a NASA Goddard Space Flight Center project for the Cassini Mission to Saturn.

Benefit from Airex Expertise

Ready to connect on how Airex can address your specific needs?