Motoring Medicine

In the 1990s, as defense spending declined, Airex shifted focus to commercial markets, finding a natural fit in the medical device industry. Their business model, featuring cutting-edge technology cost-reduced through automated manufacturing, aligned perfectly with industry needs. Airex pioneered electromagnetic implementations for pick-and-place devices, continually improving functionality.

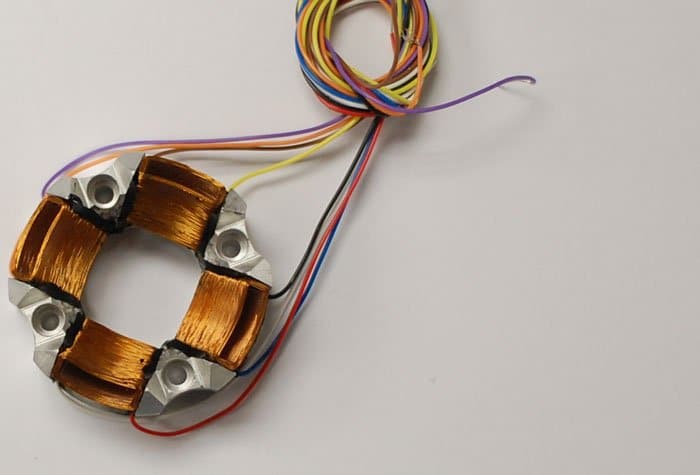

Airex’s patented motor technology remains essential for electromagnetic machinery requiring repetitive motion or precise position-holding without overheating. Advances in medical equipment spurred demand for compact, powerful motors for procedures like angioplasty, leading to new engineering projects for surgical tools such as bone saws and drills used in joint replacements.

In medical technology labs, precise acceleration and accuracy are crucial for pick-and-place applications. For instance, Airex’s linear motors excel in handling samples in environments requiring stability and controlled conditions.

Airex motors operate smoothly and efficiently, benefiting applications such as six-axis milling and grinding machines used in precise manufacturing like contact lenses molds.

Career Highlights

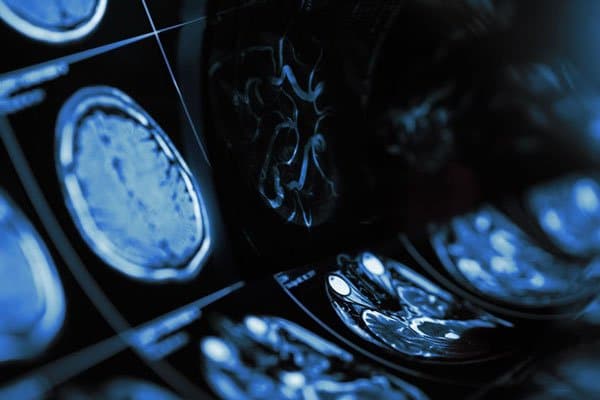

- Airex designed and developed a stationary isolation transformer for vascular imaging to aid the diagnosis and evaluation of arterial disorders

- A low-cogging, high-torque motor for surgical instruments helped reduce risk in innovative invasive procedures.

- A custom rotary transformer was developed for an innovative cardiovascular imaging system.

- A low cost, high speed motor was designed and developed for joint replacement

- High-reliability magnetics were developed and manufactured in-house in support of outpatient treatment of prostate surgery.

Benefit from Airex Expertise

The early diagnosis and evaluation of cardiac problems is critical for our aging population. We were thrilled to partner with Philips Medical Systems on the design, engineering and development of a rotary transformer that contributed to early advances in invasive cardiac imaging systems. Leaning on the technical foundation of perfectly formed coils, our engineers innovated solutions for some of the industry’s biggest challenges – often with the smallest motors. Our expertise for the medical field – and its ever-changing landscape – is unmatched in the industry, due to the innovation at the heart of our designs.

Ready to connect on how Airex can address your specific needs?