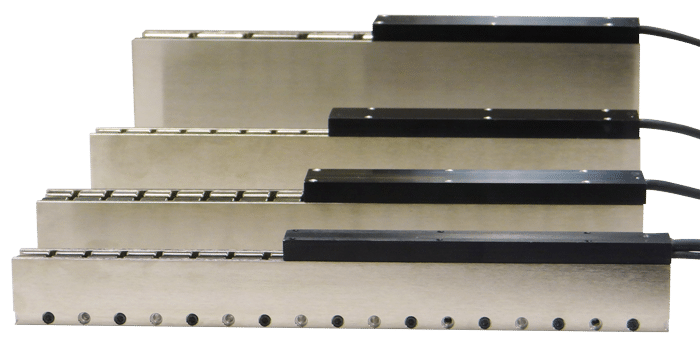

P-Series

The P-Series is our workhorse, sporting our highest force density, superb electrical phase balance, flexible in-field electrical connection choices and the largest number of configurable options, resulting in motor implementations with the highest-degree of veracity.

P12 attributes

P12 attributes

- The precise, high-performance P12 linear motor is Airex’s smallest dual-magnet U-channel motor

- Compact design of 19.1 mm (0.75”) width

- Continuous forces up to 95.3 N (21 lbs), peak forces up to 301 N (68 lbs)

P12 coil options

- LMC-P12 Coil (order code breakdown) standard coil lengths are from dash 1 to dash 4

- Series, parallel or double parallel internal connection

- P or N thermistor or K Sensor

- Cable length and list of specials

Standard magnet track lengths are: 7.2″, 9.6″, 12″, and custom lengths are available: LMDT-P12 (order code breakdown)

P15 attributes

P15 attributes

- The P15 linear motor features a dual-magnet U-channel design and compact, precise 28.6 mm (1.125”) by 45.6 mm (1.780”) profile

- Continuous forces up to 155 N (35lbs), peak forces up to 490 N (110lbs)

P15 coil options

- LMC-P15 Coil (order code breakdown) standard Coil lengths are from dash 1 to dash 5

- Series, parallel or double parallel internal connection

- P or N thermistor or F and L thermostat K Sensor

- Cable length and list of specials

Standard magnet track lengths are: 7.2″, 9.6″, 12″, and custom lengths are available: LMDT-P16 (order code breakdown)

P16 attributes

P16 attributes

- The P16 linear motor is a great low-profile motor option with plenty of performance packed into an ultra-compact track

- Cross section dimensions of 19.05 mm (0.75”) width by 54.2 mm (2.134”) tall

- Continuous forces up to 186 N (41.9 lb), peak forces up to 589 N (132 lb)

P16 coil options

- LMC-P16 Coil (order code breakdown) standard coil lengths are from dash 1 to dash 4

- Series, parallel or double parallel internal connection

- P or N thermistor or K Sensor

- Cable length and list of specials

Standard magnet track lengths are: 7.2″, 9.6″, 12″, and custom lengths are available: LMDT-P16 (order code breakdown)

P20 attributes

P20 attributes

- The P20 linear motor is the most-powerful motor in the Airex P-Series lineup

- The P20 is the industry standard for dual-magnet, U-channel linear motors

- Cross section dimensions of 35 mm (1.378”) width by 86.86 mm (3.42”) tall

- Continuous forces up to 424 N (95.3 lb), peak forces up to 1340 N (301 lb)

P20 coil options

- LMC-P20 Coil (order code breakdown) standard coil lengths are from dash 1 to dash 6

- Series, parallel or double parallel internal connection

- P or N thermistor or F and L thermostat or K Sensor

- Cable length and list of specials

Standard magnet track lengths are: 7.2″, 9.6″, 12″, and custom lengths are available: LMDT-P20 (order code breakdown)

The attributes of the P-Series make these motors ideal for:

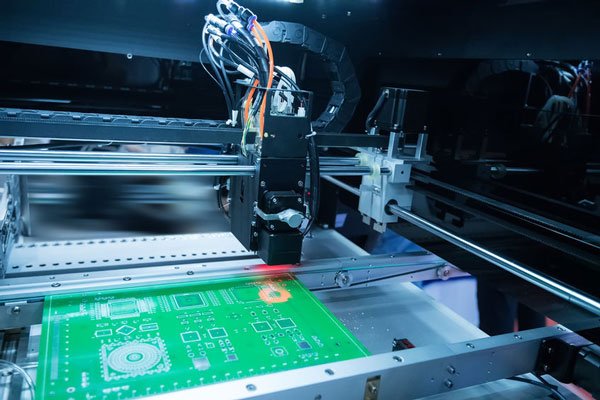

- Highest-accuracy machining

- Semiconductor wafer lithography

- High-speed scanning

- Ultra-high accuracy measuring applications

- Optical path positioning

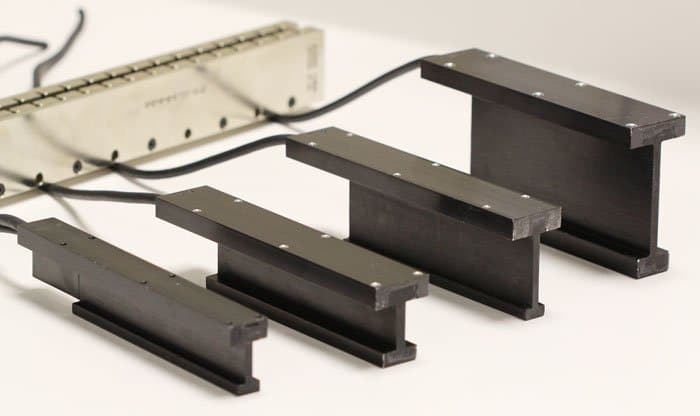

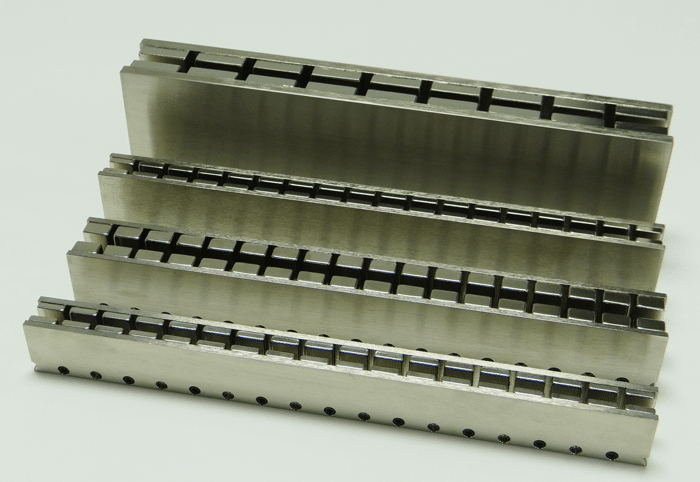

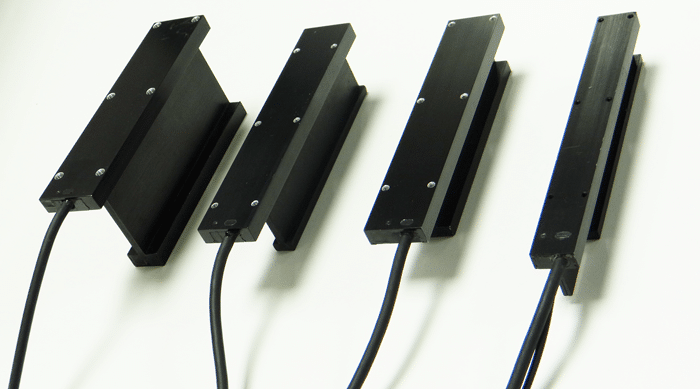

The P-Series linear motor magnet track uses high-temperature rare-earth magnets accurately located along both sides of the u-shaped assembly. Our unique and patented C-shaped coil modules are assembled back-to-back yielding a sturdy I-beam-shaped structure. The I-beam-shaped coil fits nicely between the magnets and has clearance in all directions. Once fastened to your bearing system, the coil travels back and forth inside the U-shaped channel.

The generous clearance between the coil and the magnets allows simple mounting with minimal alignment and no shimming. There’s no magnetic attraction between the coil assembly and the magnet track, thus bearing design can be biased toward accurate travel and not compromised by the need to support heavy pre-loads.

P-Series applications

Utilize P-Series motors for:

- Your most-accurate multi-tiered stages

- Inspection systems

- Micro-machining equipment

- Optical scanning devices

- Laser machining

- High-speed Pick-and-Place

The P-Series is also ideal for electrical component testing when you need very smooth motion, very high-force response, very fast settling – all with low heat rise. Applications for P-Series linear motors are numerous and specialized, and our engineers will assist you with motor recommendations, motor sizing and application.

P-Series components

The Airex magnet track uses the highest-quality nickel-plated steel and nickel-plated magnets. The standard magnet track has counter-bored through holes, while the motor coil has provisions for either side- or top-mount configurations. Numerous options for holes and threads are available – with new ones added regularly via requests. A high-flex, shielded cable allows external connections for delta or wye. The standard no-cost thermal monitoring options include positive and negative temperature coefficient thermistors.

Thermal monitoring is not limited to thermistors. We offer numerous thermal limit switches and special thermal monitoring devices that include temperature to current converters. The P-Series is available with different coil lengths, each with a corresponding incremental force rating.

The net travel distance of a P-Series motor system is equal to the length of the magnet track minus the length of the coil assembly.

P-Series Features

- Highest force density with lowest electrical time constant

- Lower heat rise for a given force

- Short time constant means the current reaches the necessary value faster and thus the motor follows profiles quicker and more accurately

- Predictable thermal performance for your most demanding application

- Accurate motion of a tool depends on knowing the thermal conditions within the moving structure. Less heating and good knowledge of the heat profile enable tool positioning to very precise locations

- Low coil assembly mass and fast response enables accelerations greater than 5G

- The low mass coils enable a system to have increased mass and yet accelerate to the same rate

- Motion velocities up to 10 m/s

- High voltage insulation in the coil enables the back electromotive force to reach the high values without breakdown

- No maintenance, non-contact brushless design and zero magnetic preload

- Six lead phase connection offers in-field customization for delta or wye or allows special ultra-low-cogging drive configurations

- Very high-flex, high-cycle count cable provides a long life

- High-quality shielded cable allows single cable motor operation

- The cable contains wires needed for phase connections, thermal device bracket ground and shield drain. For sinusoidally commutated motors, only a single motor cable is needed to run the system. Hall commutation modules have their own separate cable, which is also high flex

- Sinusoidal or Hall effect commutation options

- Commutation is the switching of currents to utilize different phases in the coil as the coil moves. (Think about climbing a rope where you need to move one hand ahead of the other. That is commutation.)

- High-performance rare earth magnets

- The stronger the magnetic field, the less current is needed to produce the same force. Heating is proportional to current squared (actually a bit more), so a small decrease in current represents a large decrease in heating

- Optimized magnet track to coil clearance gaps

- Increased gaps exponentially reduce available motor force. Our precise coil modules enable gap selections that maximize motor assembly performance with minimal manual alignment or shimming. This is important because any shimming of the coil assembly can greatly impact the required thermal cooling path

- Coils with the inherent resistance balance from machine wound coils have low inductance and thus provide exceptionally equal force response. The low inductance allows current to be changed at very high rates, enabling rapid position settling

- The P-Series winding method self balances the phase-to-phase resistance. This allows the amplifier current loop to be equally responsive no matter which coil phases it is driving. The low-inductance coil design allows the applied current to reach the desired values more rapidly than if the coils had higher inductance and longer time constants.

- Ironless zero-cogging design provides lowest velocity ripple for smoothest velocity control

- High accuracy and repeatability, zero backlash, fast settling times

- Custom options (thermal sensors, cabling, vacuum/clean room-quality) available

- Simple installation: Top/side mount coil and side mount tracks up to 24” in length

P-Series family POIs

- P12 and P16 feature the same low profile, allowing stages to be built with different force ranges at the same height.

- P15 is a great solution for a low-height, bottom mounted actuator.

- P16 and P20 are often used where a higher force and the lowest heat rise is needed.

- P12 through P16 electrical cycle pitch is 1.2”.

- P20 electrical pitch is 2.4”.

- All P-series motors use the same type of high-flex cable.

Ready to connect on how Airex can address your specific needs?